aluplast

Intelligent system solutions are becoming a reality.

Lightweight structural elements, without steel reinforcements inside the profiles, which significantly limit energy losses in buildings are new arguments and benefits that aluplast offers to window manufacturers.

Zaproponowany przez aluplast koncept energeto ® jest nowym kierunkiem w myśleniu o energooszczędności, gdyż wiąże się z wyeliminowaniem stosowanych dotychczas w profilach wzmocnień stalowych, które powodowały pogorszenie ich termiki. Dodatkowo, wdrażając tę technologię aluplast wychodzi naprzeciw oczekiwaniom producentów w zakresie optymalizowania procesów związanych z produkcją okien.

The implementation of energeto ® is possible thanks to the combination of two innovative aluplast technologies:

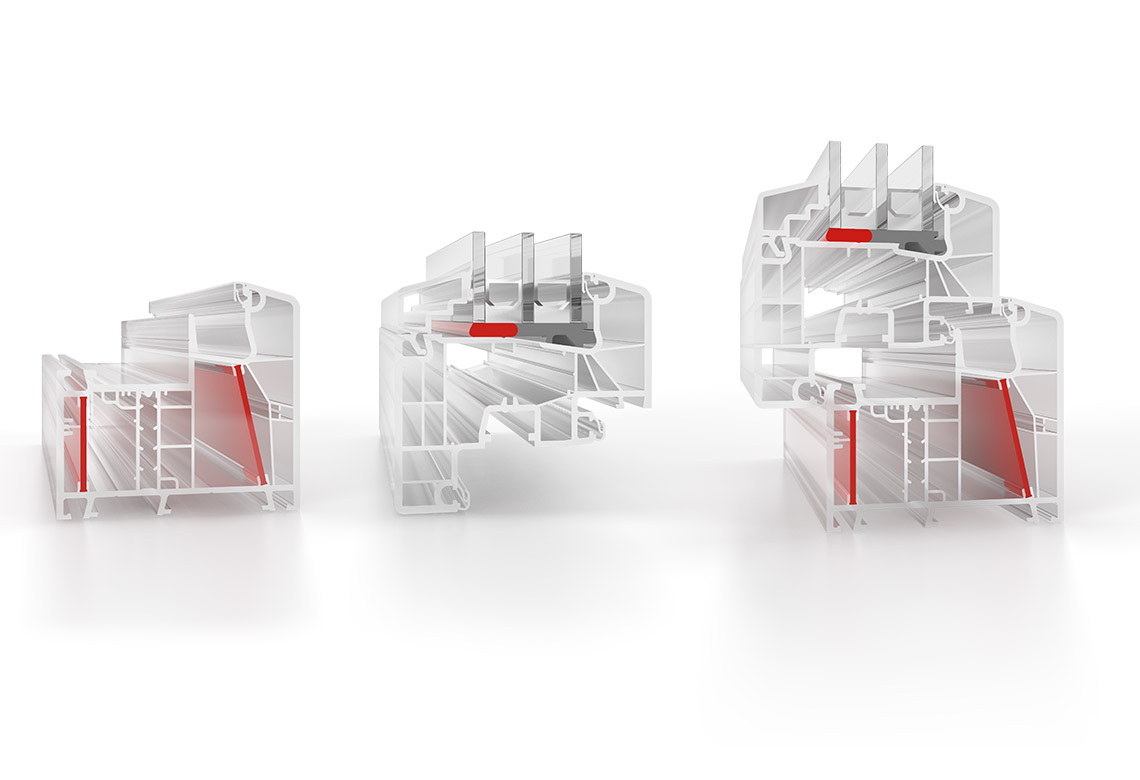

- „bonding inside“- a special sash with the technique of gluing windows

- „powerdur inside“- a new type of frame, developed in cooperation with BASF with the use of Ultradur® High Speed plastic, which replaces steel reinforcements used in conventional frames.

More functionality

energeto® is a whole range of system solutions, that is, systems with external and central sealing with a depth of 70mm, as well as a system with a central seal with a depth of 85mm. Thus, it is a comprehensive response to the market demand for windows with the best thermal insulation in the segment of new construction and renovation. The great advantage is also the possibility of improving production processes by:

- Eliminating certain operations in the window manufacturing process: ordering, storage, steel cutting (big savings in costs and time)

- Less wear of machines

- More efficient use of warehouse space (production surfaces previously occupied by steel reinforcement cutting machines and surfaces for steel warehouses are freed)

energeto® windows are raised stability and safety thanks to “bonding inside” technology

The aluplast solution enables the glass to be bonded to the wings without the use of previously needed steel reinforcements. The supporting function is taken over by the glazing unit. By bonding the glass to the profile, a significant portion of the static load is transferred through the window, which is more resistant to bending than the leaf profile, and thus stabilizes the window. Thanks to the constant connection of the pane and the wing, the risk of bending, twisting and sagging of the wing is reduced. This method minimizes the risk of window cracks due to point stresses and extends the life of the wings without the need of them being adjusted. Bonding the glass with the profile also means better protection against burglary due to the inability to push the glass out.

By changing the glazing technology it is possible to use the full depth of the glazing unit. Deeper embedment of the glass in the groove, leads to a reduction in the heat transfer coefficient of the thermal bridge occurring at the interface of the pane with the sash frame, which gives better protection against the formation of moisture on the edge of the glass.

ADVANTAGES OF WINDOW BONDING TECHNOLOGY:

- less risk of window cracking, no point glass stresses

- greater window stability thanks to the stiffening effect of the glass pane

- reducing the number of glass cracks due to faulty glazing

- increasing the glazing area - profiles are lower by approx. 10mm

- better acoustic insulation through direct connection of the wing with the glass

- better protection against burglary - the window cannot be pushed out of the sash due to the bonded perimeter

A significant reduction of the weight of the frame by as much as 60 percent, resulting from the elimination of steel is also of considerable importance. This definitely affects the comfort of work on the direct production points, as well as workers comfort involved in mounting windows at the construction site. The lower weight of the entire window also has an impact on reducing the cost of transport.

Energeto® windows are the warmest windows in their class thanks to "powerdur inside" technology

Beginning with the implementation of glass bonding technologies, actions aimed at eliminating the "weak link", which are from the point of view of thermal insulation profiles used in steel reinforcements, resulted in attempts to eliminate them completely from the sections. The metal stiffening in the profiles of the window frames creates a thermal bridge due to the high thermal conductivity. The glass fiber reinforced thermoplast replaces steel used in conventional PVC window frames and provides much better thermal insulation properties with the same mechanical properties of the window.

The elimination of steel reinforcements allowed the elimination of thermal bridges and obtained the frame heat transfer coefficient to Uf = 0,94 W/m²K. It is worth noting that very high parameters of Uf = 1,0 W/m²K were obtained even at the standard profile depth of 70 mm. It can be seen, therefore, that the research carried out allowed for a significant reduction of the thermal insulation coefficients without increasing the depth of the sections.

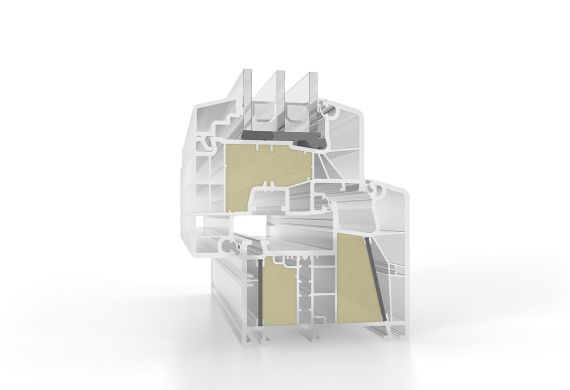

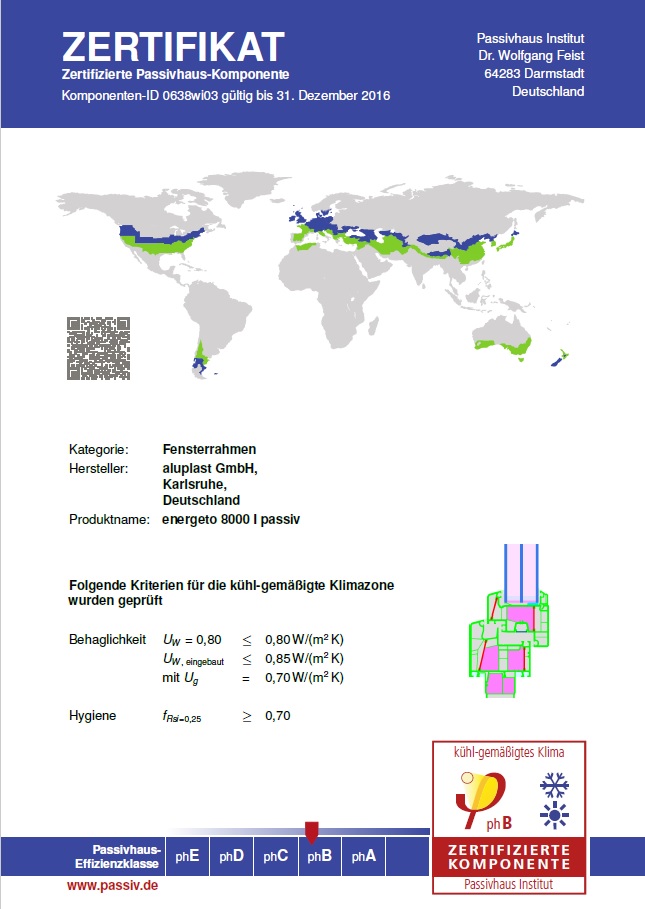

energeto® "foam inside" - windows for passive houses

Energeto® systems are one of the few window systems that allow you to create so-called passive windows already using the basic double-chamber glazing unit with a heat transfer coefficient Ug = 0,7 W/(m2*K). This is possible thanks to the use of another technical novelty introduced, i.e. the "foam inside" technology, which consists in the option of filling internal chambers with insulation material. Thanks to the introduction of a special polyurethane foam into the chambers, it is possible to obtain extremely favorable values of the heat transfer coefficient. After filling the chambers of the profiles, a heat transfer coefficient is obtained up to Uf=0,79 W/m2K, which allows obtaining a coefficient for the whole window with Uw=0,61 W/m2K. The Institute of Passive Houses in Darmstadt has issued a certificate for the energeto® 8000/ foam inside window system that recommends them as a perfect solution for passive houses.

energeto® windows - advantage thanks to innovation

Very low thermal permeability is undoubtedly the most important and basic property of energeto® window systems, which undoubtedly are the most daring window concept of recent years, based on three simultaneously realized assumptions:

- No need to use steel reinforcements in PVC profiles and replace them with thermoplastic inserts with an admixture of glass fibers

- The use of composite glazing and "bonding inside" technology ( gluing the glass into the notch of the wing) to achieve the assumed static and thermal parameters of window constructions

- Possibility of further improvement of thermal permeability of profiles by optional filling, after the bonding process of the structure, the space of some internal chambers is filled with polyurethane foam using the "foam inside" technology.