Case study: Passive House Project in Stawiguda

What will you learn from the article?

- Who built the house in Stawiguda?

- Is it worth it?

- Advantages and disadvantages of a passive house.

- How to make an aesthetically pleasing passive house?

- How was the passive house in Stawiguda built and what are its parameters?

- Windows in a passive house.

Who built a passive house in Stawiguda?

The idea came from Jacek and Zdzisław Roćko who are cofounders of the company Brawo Passive Houses. They reached out to Saint-Gobain, which is a world leader in sustainable building, to join in a collaboration. Every technology used in the project were meant to increase the energy saving qualities of the house.

What is a passive house?

Before we analyze the building process of the passive house in Stawiguda, let’s see what makes a house passive. A passive house is a house that is supposed to decrease the energy consumption and be comfortable to live. Does it sound vague? In reality, a house needs to meet a serious of criteria in order to be established as passive. Let’s check what kind of certifications did the house in Stawiguda get.

| Passive House standard | NF15 Energy Saving Standard | Saint Gobain’s Multi Comfort Standard |

| Confirmed by the Polish Institute for Passive Building and Renewable Energy and the Passivhaus Institut in Darmstadt. | Houses built to reach this standard have 15% lower energy consumption than a traditional house of the same area. | This standard focuses on four aspects of comfort: acoustic, thermal, air quality, and aesthetics. |

The realization in Stawiguda was intended, among other things, to promote Saint-Gobain's energy-efficient frame technologies.

The realization in Stawiguda was intended, among other things, to promote Saint-Gobain's energy-efficient frame technologies.

Why is it profitable to build passive houses?

Firstly, they lower the demand for energy consumption. The general insulation of the construction makes the warmth stay inside the house. In addition to that, proper installation of windows in the direction of the sun's rays allows better use of solar energy. Less energy consumption means lower bills.

Passive houses also contribute to reducing the carbon footprint. In the long term, the increasing popularity of passive houses is a step in the right direction for environmental protection.

Unfortunately, when building a passive house, you should take into consideration high costs of such project. However, after a few seasons and considering that no catastrophe is going to happen, you will experience an upside in the investment.

Design of a passive house

You can easily fall in love with the passive house in Stawiguda. You have to admit that it catches the eye. After all, one must admit that the well-thought-out body of the building with large glazing is eye-catching. The house is in no way inferior to traditional designs. Until now we did not suspect that passive construction considers the aesthetic side as one of its priorities. As you can see, we were wrong. The design is not as simple and ascetic as is the case with "standard" low-energy houses. For example, a garage and a covered ground terrace have been integrated into the body in an interesting way. They were set at a slight angle to the building. All in all, aesthetics are key.

All in all, aesthetics are key.

“Saint Gobain’s Multi-Comfort Program tries to debunk the myth that low energy and passive buildings have to be ascetic,” says Piotr Komana, Marketing and Innovation Director in Saint Gobain of the time. “Due to the usage of big and proper glazing the buildings are pretty and aesthetically pleasing from the outside as well as the inside. They add a big source of light to the interior and make the space appear bigger. Aesthetic comfort completes the comprehensive idea of the program, based on seven principles. Fulfilling all of them guarantees comfortable use while ensuring savings," he continues.

The ground terrace and garage are set at a slight slant to the main body of the building. The characteristic flat roof also attracts attention.

The ground terrace and garage are set at a slight slant to the main body of the building. The characteristic flat roof also attracts attention.

Building process of the passive house in Stawiguda

If the construction had started in the spring, it would have taken no more than five months. The work started in autumn. This and the winter season forced several interruptions. In the end, the implementation took 10 months. The house in Stawiguda has a usable area of 250 sqm. It is a single-story house with a usable attic.

In a passive building, it is of the utmost importance to achieve 100% airtightness of the barriers, especially if its construction is frame. A great deal of insulation can be packed into such walls, so it will successfully meet energy efficiency requirements. It will be more difficult to pass the airtightness test. We prepared for it extremely carefully. Our employees made sure that no accidental leakage occurred during the laying of the covering and installation. - says Mr. Jacek Roćko architect and co-owner of Brawo Domy Pasywne company.

Prefabricated house

The building consists of two wings. One of them - the bulk of it - is a prefabricated module realized with frame technology. The other, on the other hand, was erected from cellular concrete. The prefabricated elements were built with chamber-dried and four-sided planed wood.

Walls and floor

The most common way to implement foundations in passive buildings is to build a slab foundation. In the Stawiguda house, however, it is different. There we see masonry foundation walls made of concrete blocks supported on footings. Of course, effective hydro- and thermal insulation has not been forgotten. The walls were protected against moisture penetration and insulated with 27 cm thick polystyrene foam. Then an additional layer of moisture insulation was laid, on top of which there was a mesh-reinforced primer and mosaic plaster.

Between the beams, the walls were filled with an 18 cm layer of glass mineral wool. It has a very low thermal transmittance of λ = 0.031 W/(mK). On the outside, the walls were stiffened with cement-fiber mineral plates. Only on the boards was installed the insulation proper: mineral wool facade insulation. It has a slightly higher thermal conductivity coefficient λ = 0.036 W/(mK). Its thickness is as much as 25 and 26 cm.

The room under the roof slope has separate requirements. Therefore, mineral wool designed for ventilated facades was used in the attic walls. It is an insulation with the best parameters of as much as λ=0.03 W/(mK) and λ=0.031 W/(mK).

The structure is topped by a floor on the ground. The concrete floor was finished with an underfloor felt and a 30-centimeter layer of Styrofoam. In turn, an 8-centimeter layer of cement screed was poured under the floor itself.

Eliminate thermal bridges

To avoid disruption of thermal insulation and the formation of thermal bridges, the canopy over the entrance and the shed over the terrace were not connected to the building. The place through which heat loss could occur is the space under windows and doors. This loss cannot be fully avoided, even in passive houses. However, special measures can be taken to reduce it as much as possible. To further protect the woodwork and its connection to the building structure from heat loss, under-window beams or sill profiles with polyurethane foam filling are installed under windows and doors.

aluplast

Non-passive garage

The smaller of the building's wings - the one where the garage is - was built of cellular concrete. This was determined by structural considerations. A small terrace was planned above the garage, so the ceiling had to cope with a higher load. At the same time, the frame ceiling was replaced here with a reinforced concrete one. The blocks were insulated in this case no longer with mineral wool, but with facade polystyrene foam. Usually in passive houses the garage is moved away from the main body of the building. Most often it is an extension. In this case, however, it is different. The canopy over the entrance and the structure of the canopy of the ground terrace are not connected to the building, so it was possible to preserve the continuity of the thermal insulation layer. However, despite the garage's excellent insulation, it cannot be considered passive. This is due to the poor insulation performance and high leakage of the sectional door. As a result, the garage was excluded from testing.

Key aspect: windows in a passive house

Even the smallest details matter in passive realizations. So it's no surprise that builders paid great attention to windows. Windows make a passive house have an interior that is comfortable to use. Good quality air inside the building is also a plus for the health of the occupants.

Jacek Roćko recalls what challenges the Bravo team faced. - Proper sealing of windows and doors turned out to be difficult, because the frames were extended beyond the walls on special consoles. So we decided to roll up the vapor barrier film over the window recesses before installing the consoles, and then we sealed the frames with vapor barrier tape. It was glued to the windows and to the vapor barrier film, and we additionally sealed the console mounting points with butyl compound. After such procedures, we checked each window with a special device measuring air flow.

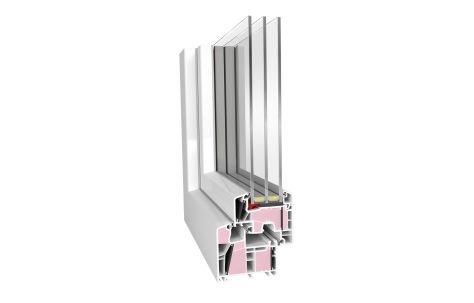

To increase the thermal insulation of the windows, some of the chambers have been filled with polyurethane foam. The windows were equipped with modern Glassolutions double-chamber glazing packages. The metal sections responsible for stiffening the frames have been replaced with special thermoplastic fiberglass inserts. The detailed parameters of specific glazing were adapted to the building design and, above all, the location of the woodwork in the facade.

aluplast

Passive windows

In passive buildings, a key aspect is the proper selection and installation of windows. The house in Stawiguda relies on six-chamber PVC windows from Adams: Passiv-line ULTRA based on the aluplast energeto 8000 system, which you can learn more about by clicking on the link. The graphic on the right shows the technology used to increase thermal insulation.

Windows with even better thermal performance were used on the northern facade. This is because, potentially, in such a location, the woodwork can become one of the thermal bridges. Ug of the glazing is 0.5 W/(m2K), Uw of the entire windows is 0.733 W/(m2K), and the g-factor is 50%. The good parameters of the window joinery meant that a relatively large area of glazing was planned on the north and east sides (17.37 m2 and 14.73 m2, respectively). On the other hand, on the south side, the windows have a total area of 32.24 m2.

For the attic, on the other hand, Velux energy-efficient roof windows with polyurethane-bonded pressure-bonded frames were chosen. This is a model with a reduced installation height. Their parameters are: Uw=0.91 W/(m2K) and Ug=0.5 W/(m2K).

Although a few years ago it was recommended to install woodwork with the highest possible solar factor, this trend in glazing design is now being abandoned. During the analysis of the first passive houses realized in Poland, it turned out that instead of passive solar heat gains, which theoretically can be used, for example, for the ventilation system with recuperation, the problem of excessive heating of rooms arises. In the case of the passive house in Stawiguda, it was decided to install woodwork with a g-factor at an average level. However, the window's performance in terms of solar energy harvesting was improved by installing shutters.

External roller shutters are installed on the skylight windows. On the other hand, external reflectors have been installed on the classic windows on the south and west sides," explains Jacek Roćko of Brawo Domy Pasywne.

Installation of windows in a passive house

A major role for the continuity of the envelope and the insulating performance of window frames is the method of installation.

- Due to the assumptions in the certificate, the window and door joinery had to be installed in the insulation layer (Isover facade mineral wool). - Jacek Roćko says - The windows were fixed with steel consoles from SFS intec, the size and number of which were individually designed. Other elements of the installation were based on illbruck solutions. ME500 Duo film was used on the inside. The space between the window frame and facade wool was filled with flexible polyurethane foam. On the outside, TP610 expansion tape was attached to the window frame and ME500 Duo film was applied at the bottom. This solution ensured adequate air tightness, confirmed during the air tightness test of the entire building. - Emphasizes the architect.

Sealing the window and door frames was a demanding task. After all, the frames were extended beyond the walls on special consoles. Before installing the consoles, therefore, the contractor rolled up the vapor barrier film over the window recesses to then seal the frames with vapor barrier film, and the places where the elements were attached also with butyl compound. After the woodwork was installed, the tightness of the joints was checked with a special device measuring air flow.

To take full advantage of the potential of large glazing, it is necessary to operate the blinds properly. Then, when it is cold, you should take care to capture as much sunlight as possible. On the other hand, on warm days it is worth lowering the blinds to avoid overheating of the building.

Passive houses are not yet a fully widespread trend in Poland. The house in Stawiguda is one of the first such projects. However, it is undeniable that passive houses are gaining popularity and more and more are being built. Less energy demand ultimately means a better state of our wallet. The most important thing, however, is that passive houses are a step towards a more sustainable for our planet building industry.

Did you like the passive house in Stawiguda? Watch the video prepared by Bravo Group: