Bonding inside

With its Bonding Inside technology, Aluplast is once again setting the trend in the industry.

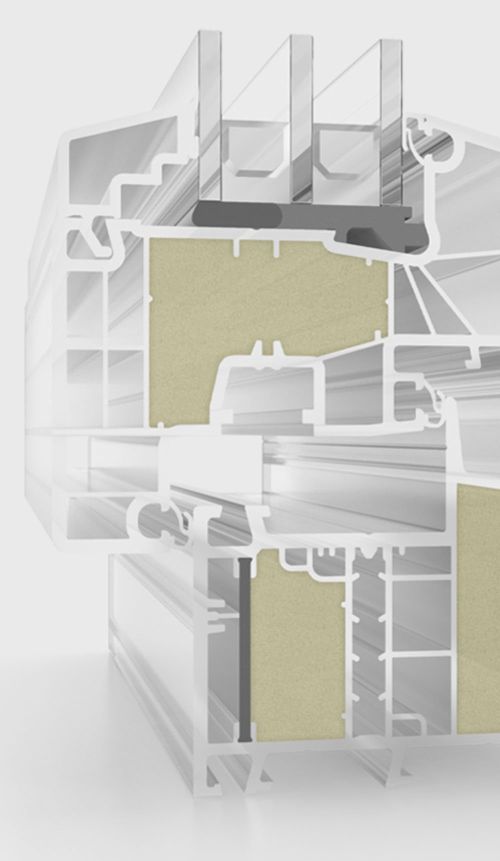

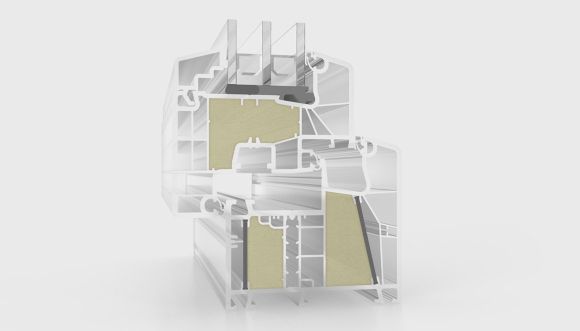

By bonding the glass to the profile with glue, around its entire perimeter, much of the static load is carried by the glass, which is more resistant to bending than the sash profile and thus stabilizes the window.

Aluplast has a comprehensive range of system solutions dedicated to the use of glass bonding technology

It is particularly important to emphasize the words “system solutions” here, since there is a whole range of profiles of the IDEAL 4000, IDEAL 5000 and IDEAL 8000 series, which are fully compatible with the other profiles.

Glazing bonding technology – greater stability and extended service life

The idea of the “bonding inside” technology is based on a change in the design principle of making the glass a structural element of the window in this solution.

The glue applied along the entire perimeter of the contact between the glass pane and the frame permanently joins them together and ensures that all glass planes are properly supported at all times, which is not only beneficial to the compensation of stresses arising in the panes of the window but also stabilizes and maintains the window’s susceptibility to deformation under the influence of forces arising from external atmospheric phenomena and operational loads within the acceptable limits.

Technology used for series production and single windows

Click to play the clip

View video

Click to play the clip

View video

Technology used for series production and single windows

Manufacturers who decide to implement this technology will certainly appreciate the reduction of operations associated with reinforcing the sash profiles with steel sections (storage, cutting, screwing) and the absence of glass blocking with spacers where glazing errors can occur.

Multifalz – “Bonding inside 4.0” glass bonding technology

The Multifalz technology from Aluplast is a system solution, consisting in the construction of multifunctional PVC profiles, which can be used both for conventional glazing with spacers and for glazing inserts. This makes it easier for manufacturers to meet the diverse needs of customers while reducing the number of stock items.

Benefits associated with glazing technology

Reduced risk of glass breakage

By distributing stresses evenly around the perimeter of the window, the phenomenon of point stresses occurring with glazing spacers is eliminated, thereby significantly reducing the risk of glass breakage during transport, installation and subsequent operation.

Greater stability of windows

Thanks to the permanent bonding of the glass and the sash, the risk of warping, bending, and any movement of the sash is reduced, thus extending the life of the sashes without the need for adjustment.

Better sound insulation

Directly bonding the sash to the glass, which does not behave like a vibrating membrane, around the perimeter.

Protection against burglary

No possibility of pushing the glass out of the sash, thanks to a perimeter gap filled with glue.

Thermal properties of the structure

Better protection against the formation of dew on the edge of the glass, along with the absence of steel reinforcements, has the effect of reducing the heat transfer coefficient of window profiles.

Larger glazed areas

The elimination of steel reinforcements allows for the design of narrower profiles. With the same dimensions of the window, the area of the glass is larger and, therefore, better illumination of the room with natural sunlight and additional thermal gains are possible.